In the dynamic world of plastic manufacturing, Plastic Masterbatches have emerged as an indispensable component, revolutionizing how producers achieve consistent color, enhanced performance, and cost-efficiency in their end products. Whether you’re manufacturing packaging films, injection-molded parts, or automotive components, understanding the value of Plastic Masterbatches is key to optimizing your production process and delivering superior results to your customers.

What Are Plastic Masterbatches, and Why Do They Matter?

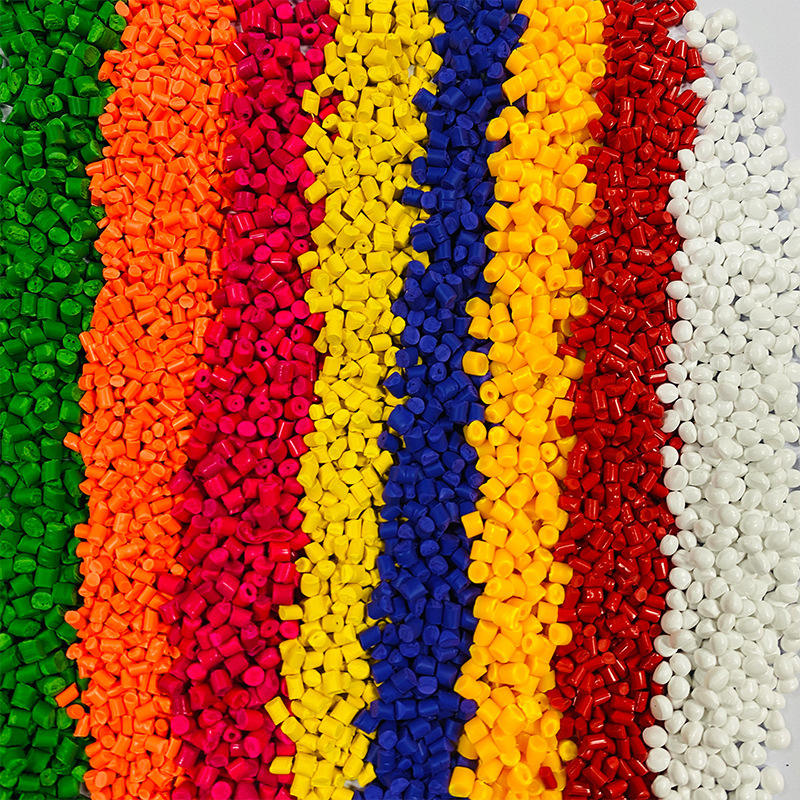

At their core, Plastic Masterbatches are concentrated mixtures of pigments, additives, or fillers that are blended with virgin or recycled plastic resins during processing. Unlike direct addition of raw pigments (which often leads to uneven dispersion and wasted material), Plastic Masterbatches are pre-dispersed in a carrier resin—ensuring uniform color distribution, stable performance, and reduced production downtime. This pre-concentrated form makes Plastic Masterbatches easy to handle, store, and integrate into existing manufacturing lines, eliminating the need for complex on-site mixing and minimizing the risk of errors.

For plastic manufacturers, the use of Plastic Masterbatches translates to tangible benefits: improved product consistency, lower material waste, and greater flexibility in customizing plastic properties. Whether you need to enhance UV resistance, add flame retardancy, or achieve a vibrant, long-lasting color, Plastic Masterbatches offer a scalable solution that adapts to diverse industry needs.

Key Applications of Plastic Masterbatches Across Industries

Plastic Masterbatches are versatile enough to serve a wide range of sectors, each leveraging their unique properties to meet specific requirements:

- Packaging Industry: Food-grade Plastic Masterbatchesare widely used in flexible films, rigid containers, and labels. They provide food-safe coloring, oxygen barrier properties, and anti-fogging additives, ensuring packaged goods remain fresh and visually appealing.

- Automotive Sector: Automotive manufacturers rely on Plastic Masterbatchesto produce interior components (e.g., dashboards, door panels) and exterior parts (e.g., bumpers, trim). These masterbatches offer heat resistance, UV stability, and scratch-proof additives, extending the lifespan of automotive plastics.

- Consumer Goods: From toys and household appliances to electronics casings, Plastic Masterbatchesenable vibrant, durable colors while meeting safety standards (e.g., non-toxic pigments for children’s products).

- Construction Industry: In pipes, fittings, and insulation materials, Plastic Masterbatchesadd UV protection and weather resistance, ensuring construction plastics withstand harsh outdoor conditions.

No matter the industry, Plastic Masterbatches streamline production, reduce costs, and elevate the quality of finished plastic products.

How to Choose the Right Plastic Masterbatches for Your Needs

Selecting high-quality Plastic Masterbatches is critical to achieving optimal results. Here are key factors to consider:

- Carrier Resin Compatibility: Ensure the carrier resin in the Plastic Masterbatchesmatches your base resin (e.g., PE, PP, PVC). Incompatible resins can cause poor dispersion, leading to uneven color or reduced mechanical performance.

- Pigment/Filler Quality: Opt for Plastic Masterbatcheswith high-purity pigments or fillers. Low-quality additives may fade over time, leach harmful substances, or compromise the structural integrity of your plastic.

- Concentration Level: The concentration of pigments/additives in Plastic Masterbatchesvaries (typically 20-80%). Choose a concentration that balances cost-efficiency with desired performance—higher concentrations mean less masterbatch is needed, but may require adjustments to your processing parameters.

- Regulatory Compliance: For industries like food packaging or healthcare, select Plastic Masterbatchesthat meet global standards (e.g., FDA, EU REACH). This ensures your products are safe for end-users and compliant with regional regulations.

- Supplier Reliability: Partner with a trusted supplier of Plastic Masterbatcheswho offers consistent quality, technical support, and custom formulations. A reliable supplier can help tailor Plastic Masterbatches to your unique production needs, from custom colors to specialized additives.

The Future of Plastic Masterbatches: Innovation and Sustainability

As the plastic industry shifts toward sustainability, Plastic Masterbatches are evolving to meet eco-friendly demands. Manufacturers are now developing Plastic Masterbatches using recycled carrier resins, bio-based pigments, and additives that enhance the recyclability of plastic products. These sustainable Plastic Masterbatches not only reduce environmental impact but also help brands meet their sustainability goals without sacrificing performance.

Additionally, technological advancements are improving the dispersion efficiency of Plastic Masterbatches, allowing for higher concentrations of additives and thinner film applications. This innovation is making Plastic Masterbatches even more cost-effective and versatile, opening new possibilities for plastic manufacturers worldwide.

Conclusion

Plastic Masterbatches are more than just a coloring agent—they are a strategic tool that enhances the performance, consistency, and sustainability of plastic products. By choosing the right Plastic Masterbatches and partnering with a reputable supplier, you can optimize your production process, reduce costs, and deliver high-quality plastic goods that stand out in the market. Whether you’re a small-scale manufacturer or a large industrial player, investing in premium Plastic Masterbatches is a step toward long-term success in the competitive plastic industry.

If you’re looking for customized, high-performance Plastic Masterbatches tailored to your specific needs, our team of experts is here to help. Contact us today to learn more about our range of Plastic Masterbatches and how we can support your production goals.

Learn more about our products at: www.broyalpigment.com

Contact: admin@cnbroyal.com

Whatsapp/WeChat: +86 13539645146